ARIHANT ENGINEERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ARIHANT ENGINEERS

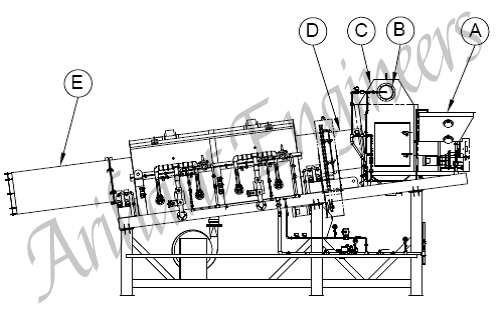

Thermal Chip Drier

Functional Description

Chips from machining operations are fed into the screw feeder hopper (A). The screw feeder feeds the chips into the rotary hearth (D) at a constant rate. In the rotary hearth, the chips are typically heated to a set point temperature between 800 and 900°F to vaporize the water and oil. Products inside the rotary hearth (D) are indirectly heated. Natural gas fired burners/furnace oil burner to heat the rotary hearth from the outside. These burners are fired into a cavity between the outside of the rotary hearth and in-side of the furnace shell refractory. There is no direct flame impingement on the chips or extreme temperatures that could result in surface oxidation of the chips.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.